Ridge Carbide Saw Blades: A Guide for Woodworkers of All Levels

Woodworking is a craft that requires not only skill and creativity, but also the right tools. One of the most important tools in any woodworker’s arsenal is the saw blade. A high-quality saw blade can make the difference between a clean, precise cut and a rough, uneven one. In this article, we will take a deep dive into Ridge Carbide saw blades, exploring their features, benefits, and different varieties to help you choose the perfect blade for your next project.

Ridge Carbide: A Reputation for Quality

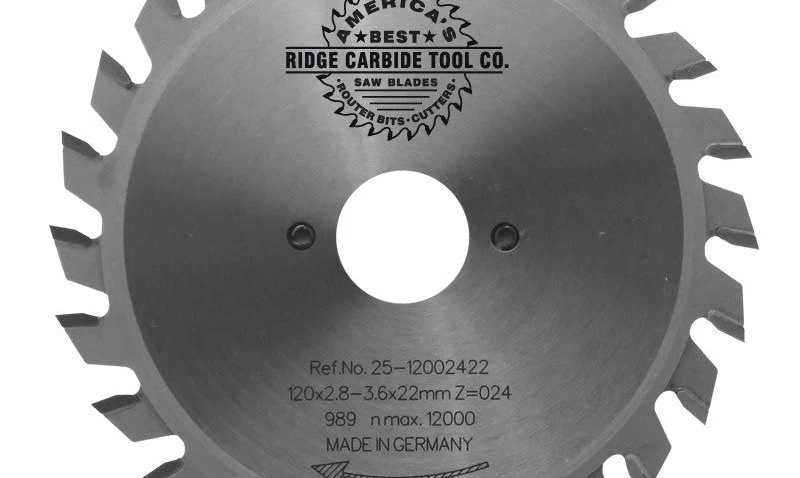

Ridge Carbide Tool is a reputable manufacturer of saw blades, router bits, and other woodworking accessories. They are known for their commitment to quality and innovation, using premium materials and advanced designs to create blades that are both durable and effective. Ridge Carbide saw blades are made with C-4 carbide teeth, a type of tungsten carbide known for its exceptional hardness and wear resistance. This ensures that the blades stay sharp longer, reducing the need for frequent sharpening and replacements.

Benefits of Ridge Carbide Saw Blades

There are several advantages to using Ridge Carbide saw blades in your woodworking projects. Here are some of the key benefits:

- Clean Cuts: Ridge Carbide blades are designed to produce smooth, clean cuts with minimal chipping or tear-out. This is especially important for fine woodworking projects where precision is paramount.

- Long-lasting Performance: The C-4 carbide teeth ensure that the blades stay sharp for an extended period of time. This translates to fewer blade changes and more time spent on your project.

- Versatility: Ridge Carbide offers a wide variety of saw blades designed for different purposes. Whether you need a blade for ripping hardwood, crosscutting plywood, or making fine joinery cuts, there’s a Ridge Carbide blade that’s up to the task.

- Value for Money: While Ridge Carbide blades may be priced slightly higher than some budget brands, their extended lifespan and superior performance make them a worthwhile investment in the long run.

Choosing the Right Ridge Carbide Saw Blade

With a wide range of saw blades available, selecting the right one for your project can seem daunting. Here are some key factors to consider:

- Saw Type: The first step is to identify the type of saw you will be using the blade with. Ridge Carbide offers blades specifically designed for table saws, miter saws, radial arm saws, and more.

- Blade Size: Saw blades come in different diameters to fit various saws. Make sure the blade diameter you choose matches your saw’s specifications.

- Number of Teeth: The number of teeth on a saw blade determines the type of cut it excels at. Blades with fewer teeth (typically 24-40 teeth) are ideal for ripping, while blades with more teeth (typically 60 or more teeth) are better suited for crosscutting and achieving a smoother finish.

- Kerf Width: The kerf refers to the width of the cut made by the blade. A thinner kerf blade wastes less material, but it may also be more fragile.

Popular Ridge Carbide Saw Blade Options

Let’s explore some of the most popular Ridge Carbide saw blade options to give you a better idea of what they offer:

- Ridge Carbide TS2000 Super Combo Blade: This 10-inch, 40-tooth blade is a versatile option that can handle both ripping and crosscutting tasks with ease. It features a raker tooth design for smooth cuts and C-4 carbide teeth for long-lasting performance.

- Ridge Carbide Miter Saw Blade: This 10-inch, 60-tooth blade is specifically designed for miter saws. It features a negative hook angle for clean crosscuts and minimizes bottom splintering.

- Ridge Carbide TS2000 Flat Top Box Joint Blade: This unique blade is designed for cutting box joints and finger joints. It has a flat top grind that ensures a clean, square cut for perfect joinery.

Beyond the Blades: Tips for Success with Ridge Carbide

In addition to using high-quality saw blades, here are some additional tips to ensure success in your woodworking projects:

- Use the Right Blade for the Job: Matching the blade to the task at hand is crucial for achieving clean cuts and optimal performance.

- Maintain Your Blades: Regularly cleaning and sharpening your saw blades will extend their lifespan and ensure they continue to perform at their best.

- Use Proper Saw Techniques: Proper feeding technique and saw setup are essential for safe and efficient cutting.

Competitive Analysis

Ridge Carbide has established itself as a strong contender in the saw blade market, but it’s not the only player in the game. Here’s a breakdown of how Ridge Carbide stacks up against some of its leading competitors:

Freud:

- Reputation: Freud is a well-established brand with a long history of producing high-quality saw blades.

- Price: Freud offers blades at a variety of price points, catering to both budget-conscious and professional woodworkers.

- Selection: Freud boasts a wide selection of saw blades for different applications, similar to Ridge Carbide.

- Strengths: Freud blades are known for their good balance of value and performance.

Forrest:

- Reputation: Forrest is a premium brand renowned for its exceptional blade quality and longevity.

- Price: Forrest blades are typically the most expensive option on this list.

- Selection: Forrest offers a more limited selection of blades compared to Ridge Carbide or Freud, focusing on high-end performance blades.

- Strengths: Forrest blades are ideal for woodworkers who prioritize absolute precision and cutting performance.

Customer Service and Support

While the previous article focused on the features and benefits of Ridge Carbide saw blades, it’s important to know where to turn for help if you encounter any issues or have questions. Here’s what we know about Ridge Carbide’s customer service and support options:

Contact Methods

- Website: Ridge Carbide doesn’t explicitly list a phone number for customer service on their website.

- Email: You can potentially reach customer service via email, although there’s no dedicated email address listed publicly. You might try contacting them through the “Contact Us” form and inquire if they have an email address for support.

Support Resources

Here are some resources that might be helpful:

- FAQ Section: While Ridge Carbide doesn’t appear to have a dedicated FAQ section on their website, they might have informational videos or blog posts that address common customer questions. You can try searching their website for relevant keywords.

- Manuals and Guides: Ridge Carbide might offer downloadable manuals or guides for their saw blades. These resources can provide valuable information on proper blade use, maintenance, and troubleshooting. Check the product page for your specific blade or search their website for “manuals” or “guides.”

Additional Tips

- Social Media: While not a direct line for support, you can try contacting Ridge Carbide through their social media channels (if they have any) to see if they can point you in the right direction.

- Online Reviews: Customer reviews on retailer websites where Ridge Carbide products are sold can sometimes offer insights into user experiences and potential troubleshooting tips.

Remember: When contacting customer service, be prepared to provide details about your inquiry, such as the specific saw blade you have, the nature of the issue you’re facing, and any relevant information about your project.

By utilizing the available resources and providing clear information, you’ll increase your chances of receiving prompt and effective assistance from Ridge Carbide.

Ridge Carbide saw blades are a great option for woodworkers of all levels. Their combination of quality materials, innovative design, and versatility makes them a valuable addition to any workshop. By understanding the different types of blades available and choosing the right one for your project.

Leave a Reply