Mastering the Straight Cut: A Guide to Using a Circular Saw

Cutting a straight line with a circular saw might seem simple, but it’s a skill that requires practice and precision. Whether you’re a seasoned DIYer or a novice, understanding the fundamentals is crucial. This article will guide you through the process, from selecting the right tools to executing the perfect cut.

Understanding Your Tools

Before diving into the cutting process, it’s essential to familiarize yourself with your tools. A circular saw is the primary tool, but there are other accessories that can significantly improve your accuracy.

- Circular Saw: The heart of the operation. Look for a saw with a blade that suits your material. For most woodworking projects, a general-purpose blade will suffice.

- Clamps: These hold your workpiece securely in place, preventing movement during the cut.

- Measuring Tape: Accurate measurements are the foundation of any project.

- Pencil or Marker: Clearly mark your cutting line.

- Straight Edge: A long, straight piece of wood or metal to guide your saw.

- Safety Gear: Always wear safety glasses, ear protection, and gloves.

Preparing for the Cut

Proper preparation is key to achieving a straight cut.

- Choose the Right Blade: The type of blade you use will affect the quality of your cut. For most woodworking projects, a general-purpose blade is suitable. However, for specific materials like plywood or laminate, you might need a different blade.

- Secure Your Workpiece: Use clamps to hold your material firmly in place. This prevents movement and ensures a clean cut.

- Mark the Cutting Line: Use a pencil or marker to create a clear, visible line where you want to cut. Double-check your measurements to avoid mistakes.

- Set Up Your Saw: Adjust the blade depth to slightly exceed the thickness of your material. This prevents binding and ensures a smooth cut.

Cutting Techniques

There are several methods to achieve a straight cut with a circular saw. Here are a few popular options:

Freehand Cutting

Freehand cutting requires practice and a steady hand.

- Start Slowly: Begin the cut slowly to establish a straight line.

- Maintain Even Pressure: Apply consistent pressure to the saw as you move it along the cutting line.

- Watch the Blade: Keep your eyes on the blade to maintain accuracy.

While freehand cutting can be challenging, it’s a valuable skill to develop.

Using a Straight Edge

A straight edge provides a guide for your saw, significantly improving accuracy.

- Clamp the Straight Edge: Securely clamp the straight edge to your workpiece, ensuring it aligns with your cutting line.

- Position the Saw: Place the saw’s base plate against the straight edge.

- Make the Cut: Slowly and steadily guide the saw along the straight edge.

This method is ideal for longer cuts or when precision is essential.

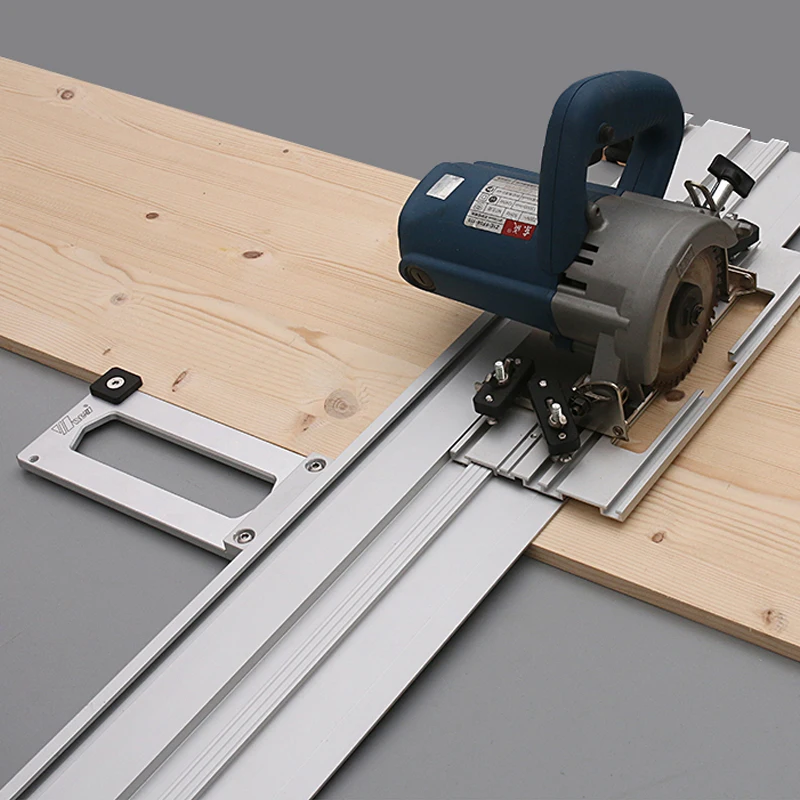

Using a Circular Saw Track

A circular saw track is a specialized tool designed for precise straight cuts.

- Assemble the Track: Follow the manufacturer’s instructions to set up the track.

- Clamp the Track: Securely clamp the track to your workpiece, ensuring it aligns with your cutting line.

- Attach the Saw: Attach the saw to the track according to the manufacturer’s instructions.

- Make the Cut: Guide the saw along the track for a perfectly straight cut.

Circular saw tracks are excellent for achieving professional-quality results.

Offer tips for maintaining a steady hand

Achieving a straight cut often boils down to control and steadiness. Here are some tips to help you master your circular saw:

Body Positioning and Grip

- Stance: Maintain a balanced and stable stance. Your feet should be shoulder-width apart for good support.

- Grip: Hold the saw firmly with both hands. Your dominant hand should be on the saw’s upper handle, and your other hand on the front handle.

- Elbows: Keep your elbows slightly bent for better shock absorption and control.

Saw Operation

- Start Slowly: Begin the cut slowly and gradually increase speed as you gain confidence.

- Even Pressure: Apply consistent, even pressure to the saw. Avoid pressing too hard, as this can cause the saw to bind.

- Blade Alignment: Ensure the blade is perpendicular to the workpiece. Any angle will affect the cut.

- Follow-Through: Continue the cut smoothly until the saw is completely out of the material. Avoid lifting the saw before the blade has cleared the workpiece.

Additional Tips

- Practice: Regular practice is key to improving your control. Start with smaller, less critical pieces of wood to build confidence.

- Safety Gear: Always wear safety glasses, ear protection, and gloves. Proper gear can help you focus on the task at hand.

- Blade Condition: A sharp, well-maintained blade reduces vibration and makes cutting smoother.

- Work Area: Ensure your workspace is well-lit and free of clutter. A clean workspace promotes focus and safety.

Remember, patience and practice are essential. Don’t get discouraged if your first few cuts aren’t perfect. With time, you’ll develop the muscle memory and coordination needed for precise cuts.

Identify common mistakes that can lead to an inaccurate cut

Achieving a perfectly straight cut with a circular saw requires more than just turning it on and pressing it forward. Several common mistakes can lead to inaccurate cuts. Understanding these errors is crucial to improving your sawing skills.

Setup Errors

- Incorrect Blade Depth: If the blade doesn’t fully cut through the material, it can bind and cause the saw to veer off course. Always ensure the blade extends slightly beyond the material’s thickness.

- Loose or Damaged Blade: A loose or damaged blade can vibrate, causing the saw to wander. Regularly inspect your blade for damage and tighten it securely.

- Improper Bevel Angle: Setting the wrong bevel angle will result in angled cuts rather than straight ones. Double-check the angle before cutting.

Technique Errors

- Uneven Pressure: Applying inconsistent pressure on the saw can lead to curved cuts. Maintain a steady, even pressure throughout the cut.

- Tilting the Saw: Tilting the saw while cutting will produce angled cuts. Keep the saw base flat on the workpiece.

- Not Supporting the Material: If the material is not adequately supported, it can flex or bend, resulting in an inaccurate cut. Use sawhorses or clamps to support the workpiece.

Measurement and Marking Errors

- Inaccurate Measurements: Measuring errors are a primary cause of inaccurate cuts. Double-check all measurements before cutting.

- Faulty Cutting Line: A poorly marked cutting line can lead to deviations from the desired cut. Use a sharp pencil or marker and a straight edge for precise marking.

Safety Oversights

- Incorrect Grip: A poor grip on the saw can affect its control and lead to unintended movements. Maintain a firm grip with both hands.

- Ignoring Kickback: Kickback is a dangerous and unpredictable force that can cause the saw to jump. Avoid binding the blade and be prepared to react if it happens.

Material-Related Issues

- Warped or Twisted Material: Cutting warped or twisted material can be challenging and lead to inaccurate cuts. If possible, straighten the material before cutting.

- Material Density: Different materials have varying densities, which can affect the cutting process. Adjust the blade speed and feed rate accordingly.

By understanding and avoiding these common mistakes, you can significantly improve the accuracy of your circular saw cuts. Remember, practice makes perfect. The more you use your circular saw, the better you’ll become at achieving precise results.

Tips for a Perfect Cut

- Practice Makes Perfect: The more you practice, the better you’ll become at cutting straight lines.

- Start Small: Begin with smaller projects to build your confidence.

- Check Your Blade: A dull blade can cause inconsistent cuts. Replace it when necessary.

- Take Your Time: Rushing can lead to mistakes. Slow and steady wins the race.

- Clean Up: Remove sawdust and debris from your workspace to prevent accidents.

By following these guidelines and practicing regularly, you can master the art of cutting straight lines with a circular saw. Remember, safety should always be your top priority. Wear appropriate protective gear and follow the manufacturer’s instructions for your tools.

Leave a Reply