Don’t Get Cut Off: A Guide to Circular Saw Blade Direction

The circular saw is a workhorse in any workshop, offering versatility for ripping lumber, making crosscuts, and tackling various cutting projects. But before you unleash its power, there’s a crucial detail to ensure clean cuts and, more importantly, safety: circular saw blade direction. Installing the blade incorrectly can lead to binding, kickback, and serious injuries.

This comprehensive guide delves into the world of circular saw blade direction, equipping you with the knowledge to confidently tackle any cutting task. We’ll explore the fundamentals, common pitfalls, and helpful tips to ensure your blade is always spinning in the right direction.

Understanding the Importance

So, why exactly does circular saw blade direction matter? Here’s the breakdown:

-

Cutting Action: A circular saw blade features teeth designed to rotate and grab the material being cut. When installed correctly, the teeth act like tiny hooks, pulling the material down and into the body of the saw. This creates a clean, controlled cut.

-

Safety First: Incorrect blade direction fundamentally changes how the saw interacts with the material. With the teeth facing the wrong way, the blade can push the material back towards the user, increasing the risk of kickback – a sudden, violent upward motion of the saw. This can cause loss of control and serious injury.

-

Material Damage: An improperly installed blade can tear and splinter the wood, leaving behind rough and uneven cuts. This defeats the purpose of a clean, precise cut and necessitates additional work on the material.

In essence, getting the blade direction right is a no-brainer. It ensures your safety, protects your tools, and delivers the quality cuts your projects deserve.

Identifying the Correct Direction

Now that we’ve established the significance of proper blade direction, let’s get down to the specifics of identifying it. Thankfully, most circular saws come equipped with helpful visual cues:

-

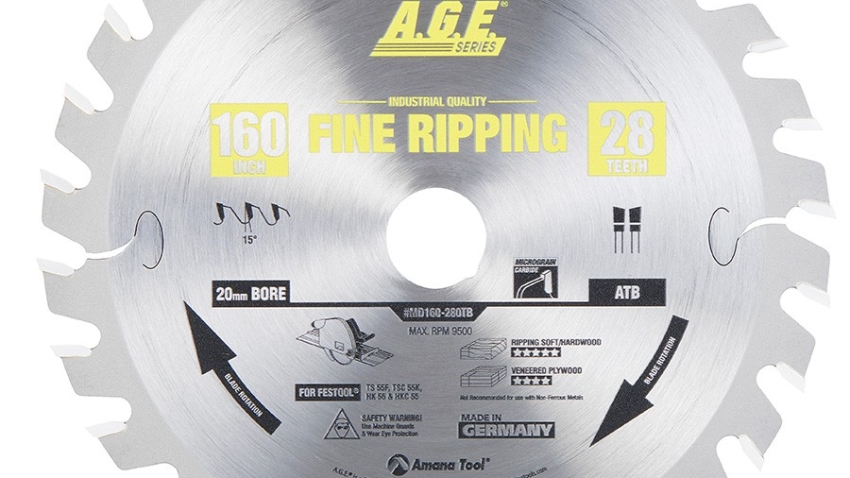

Blade Arrow: Many blades have a directional arrow etched onto their body. This arrow should point towards the front of the saw, indicating the direction the teeth need to face during installation.

-

Saw Guard Arrow: The saw guard, a protective component surrounding the blade, often features a similar directional arrow. Once again, this arrow should align with the arrow on the blade for proper installation.

-

Blade Label: Some blades might have a label specifying the “cutting face” or “feed direction.” Ensure this side faces outwards when mounted on the saw.

If your saw or blade lacks these visual aids, a simple rule of thumb applies: the teeth should always point downward towards the material being cut. Imagine the saw resting flat on a table. The teeth should be angled to grab the material beneath the baseplate and pull it upwards into the saw.

Common Mistakes and How to Avoid Them

Even with clear guidelines, mistakes can happen. Here are some common pitfalls to watch out for:

-

Prioritizing Aesthetics: Some blades have a smooth, finished side that might be tempting to face outwards for a cleaner look. However, resist this urge! Always prioritize the directional arrows or ensure the teeth are pointed downwards for safe and effective cutting.

-

Confusing Blade Rotation with Teeth Direction: The circular saw blade spins at a high velocity. It’s easy to get confused between the overall rotation of the blade and the direction the teeth point. Remember, we’re concerned with the angle of the teeth, not the overall direction the blade spins.

-

Relying Solely on Memory: Don’t trust your memory, especially if you work with the saw infrequently. Double-check the blade direction every time you change a blade. It’s a quick and crucial step that can prevent accidents.

Additional Tips for Success

Here are some bonus tips to make sure your circular saw blade direction is always on point:

-

Invest in a Blade with Clear Markings: If you find yourself constantly struggling to identify the blade direction, consider purchasing blades with prominent and easy-to-understand arrows or labels.

-

Develop a Habitual Check: Make it a habit to check the blade direction every single time you install a new blade, regardless of how familiar you are with the process. Consistency is key to safety.

-

Keep a User Manual Handy: Most circular saw user manuals come with detailed instructions on blade installation, including diagrams and explanations on proper blade direction. Refer to this manual whenever needed.

-

Don’t Be Afraid to Ask for Help: If you’re unsure about anything related to your circular saw, including blade direction, don’t hesitate to seek help from a professional at a hardware store or a woodworking expert.

By following these guidelines and incorporating these tips into your routine, you can ensure your circular saw blade is always spinning in the right direction, guaranteeing safe and successful cutting experiences. Remember, taking a few extra seconds to verify blade direction can save you time, money, and most importantly, prevent injury.

Beyond the Basics: Advanced Considerations

While understanding the fundamentals is crucial, there’s more to circular saw blade direction than meets the eye. Here, we’ll delve into some advanced considerations for experienced users:

Blade Type and Material:

The optimal blade direction might vary slightly depending on the specific blade type and the material you’re cutting. For example, some blades designed for ripping thin plywood might benefit from a “negative hook angle,” where the teeth are angled slightly backward. However, this is an exception. For most standard circular saw blades and common cutting tasks, the teeth should still point downwards.

Climb Cut vs. Conventional Cut:

There are two primary cutting techniques with circular saws: climb cutting and conventional cutting. In climb cutting, the blade rotates in the same direction the cut is being made. Conversely, conventional cutting has the blade spinning opposite the direction of the cut. While climb cutting can offer a smoother finish under certain circumstances, it’s generally considered more dangerous due to the increased risk of kickback. Therefore, conventional cutting is the preferred method for most users. In conventional cutting, the blade direction remains the same – teeth pointing downwards.

Left-Handed Blades (Rare Cases):

In rare instances, you might encounter left-handed circular saw blades designed for specific applications. These blades have their teeth pointing in the opposite direction compared to standard blades. However, left-handed blades are not commonly used, and it’s always best to consult the manufacturer’s instructions if you encounter one.

Remember, these advanced considerations are for experienced users who are comfortable with different cutting techniques and blade types. If you’re new to circular saws, prioritize the basic principle: teeth point downwards towards the material being cut for safe and effective operation.

Taking Care of Your Blades

Once you’ve mastered the art of installing your circular saw blade in the right direction, here are some additional tips to extend the life and performance of your blades:

-

Store Them Properly: Don’t toss your blades haphazardly in a toolbox. Invest in a dedicated storage case to protect the teeth from damage.

-

Clean Them Regularly: Wood resin and debris can build up on the blade, affecting its cutting efficiency. Wipe down your blades periodically with a degreaser or a light solvent to maintain optimal performance.

-

Sharpen When Needed: Circular saw blades become dull over time, leading to rough cuts and increased effort required for pushing the saw. Consider having your blades professionally sharpened to restore their cutting edge.

-

Replace When Worn Out: Even with proper care, blades eventually wear out. Replace dull or damaged blades promptly to ensure safety and efficient cutting.

By following these practices, you’ll get the most out of your circular saw blades, ensuring they stay sharp, safe, and ready to tackle any cutting project you throw their way.

Understanding circular saw blade direction is a fundamental skill for any user. This guide has equipped you with the knowledge to confidently install your blades and make clean, safe cuts. Remember, prioritize the basic principle – teeth point downwards – and don’t hesitate to consult resources or seek help if needed. With the right knowledge and a focus on safety, your circular saw will become a reliable and versatile tool in your workshop for years to come.

Leave a Reply