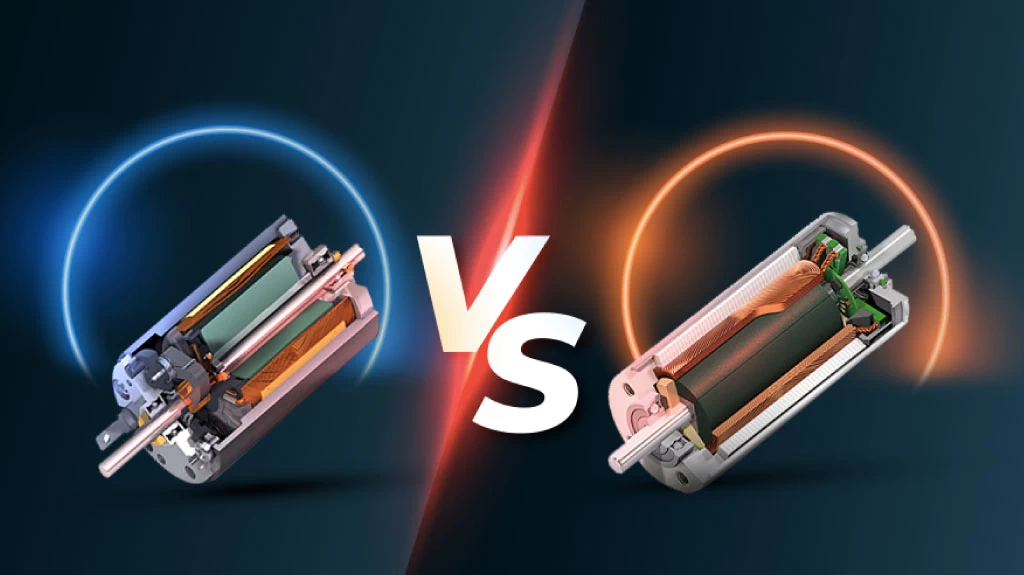

Brushed vs. Brushless Power Tools: Unveiling the Power Within

The world of DIY and professional construction is abuzz with power tools. But for those new to the scene, choosing the right equipment can be daunting. A crucial decision lies in the heart of the tool itself: the motor. Two main types dominate the market – brushed and brushless. Understanding their strengths and weaknesses will empower you to make informed choices for your next project.

Brushed Motors: The Workhorse with Age

Brushed motors are the veterans of the power tool scene. Their design is relatively simple and well-established. Two carbon brushes make contact with a commutator, a segmented cylinder that rotates within the motor. As electricity flows through the brushes, it creates a magnetic field that interacts with permanent magnets fixed inside the motor housing. This interaction causes the motor shaft to spin.

The brushed motor’s simplicity translates to affordability. They are generally less expensive than their brushless counterparts. Additionally, their design makes them relatively easy to maintain and repair. For occasional DIY projects or light-duty tasks, brushed motors can be perfectly adequate.

However, brushed motors come with some drawbacks. The constant friction between the brushes and the commutator generates heat and sparks. This friction wears down the brushes over time, reducing efficiency and necessitating replacements. The heat also shortens the lifespan of the motor itself. Furthermore, brushed motors tend to be bulkier and heavier due to the additional components involved.

Brushless Motors: The Cutting-Edge Choice

Brushless motors represent a leap forward in power tool technology. Unlike their brushed counterparts, they eliminate the need for physical brushes and commutators. Instead, they rely on permanent magnets on the rotor (spinning part) and electromagnets on the stator (stationary part). A complex electronic circuit, controlled by a microprocessor, energizes the electromagnets in a precise sequence. This creates a rotating magnetic field that pulls the permanent magnets on the rotor, causing it to spin.

The absence of brushes brings numerous advantages. Brushless motors are significantly more efficient. With no friction from brushes, they generate less heat, leading to longer battery life, cooler operation, and ultimately, a longer lifespan for the motor. Additionally, brushless motors are generally more compact and lighter due to the simpler design. This translates to better handling and maneuverability for the user.

The lack of sparking also makes brushless motors a safer choice, especially in environments where flammable materials are present. Furthermore, the electronic control allows for more precise speed control and variable torque settings, making brushless motors more versatile for a wider range of tasks.

The Great Brushed vs. Brushless power tools Showdown: Choosing Your Champion

So, which motor technology reigns supreme? The answer, like most things in life, depends on your specific needs and priorities. Here’s a breakdown to help you decide:

- Budget: Brushed motors are the clear winner on price. If you’re a casual DIYer or need a tool for infrequent use, a brushed motor can be a cost-effective option.

- Power and Performance: Brushless motors deliver more power, torque, and efficiency. This translates to faster drilling, cutting, and driving, making them ideal for professionals or those tackling heavy-duty projects.

- Runtime: Brushless motors offer significantly longer battery life, crucial for extended work sessions or situations where access to power outlets is limited.

- Durability: Due to reduced friction and heat generation, brushless motors generally have a longer lifespan than brushed motors.

- Weight and Size: Brushless motors are typically more compact and lightweight, making them easier to handle and maneuver, especially during long periods of use.

- Maintenance: Brushless motors require minimal maintenance, eliminating the need for brush replacements.

Beyond Brushed vs. Brushless power tools: Additional Considerations

While brushed and brushless are the primary motor technologies, there are other factors to consider when choosing a power tool:

- Battery Platform: Many manufacturers offer a range of tools that share the same battery platform. This allows you to purchase multiple tools without needing separate batteries and chargers.

- Ergonomics: Consider the weight, size, and grip of the tool to ensure it feels comfortable in your hand and reduces fatigue during use.

- Features: Look for features that enhance functionality, such as variable speed control, LED lights, and dust collection ports.

Components and operation of brushed motors

Brushed motors, the workhorses of the power tool world, function thanks to a relatively simple interplay between a few key components:

- Stator: This is the stationary outer part of the motor. It typically houses permanent magnets, although in some cases electromagnets might be used.

- Rotor (Armature): The rotor is the spinning part of the motor. It consists of a central shaft with a core made of laminated steel. Wrapped around this core are coils of wire, forming electromagnets.

- Commutator: This is a cylindrical component made of segmented copper plates attached to the rotor’s shaft. It acts as a bridge between the electrical supply and the coils on the rotor.

- Brushes: These are spring-loaded carbon contacts that press against the commutator. They conduct electricity from the power source to the coils in the rotor.

Here’s how power tools all works:

- Electrical Connection: When you turn on the power tool, electricity flows through the brushes.

- Magnetic Field Creation: The current flowing through the coils in the rotor creates a magnetic field around them.

- Magnetic Interaction: This magnetic field interacts with the permanent magnets in the stator, repelling and attracting them depending on the polarity.

- Commutator’s Role: As the rotor spins, the commutator segments come into contact with the brushes, constantly changing the direction of current flow through the coils.

- Continuous Rotation: This continuous change in magnetic field direction between the rotor and stator creates a force that causes the rotor to spin.

The commutator and brushes are the key elements that differentiate brushed motors. However, this design also has its drawbacks, as the constant friction between the brushes and commutator generates heat and wear, requiring maintenance and limiting efficiency.

The Final Verdict: Powering Up Your Projects

Brushed and brushless motors each have their strengths and weaknesses. By understanding these differences and considering your individual needs, you can make an informed decision and select the right power tool for the job. If you prioritize affordability and occasional use, a brushed motor might suffice. However, for power, performance, and long-term value, a brushless motor is a worthwhile investment. Ultimately, the choice empowers you to tackle your projects with confidence and efficiency.

Leave a Reply