The Versatile Band Saw: A Workhorse for Diverse Cutting Needs

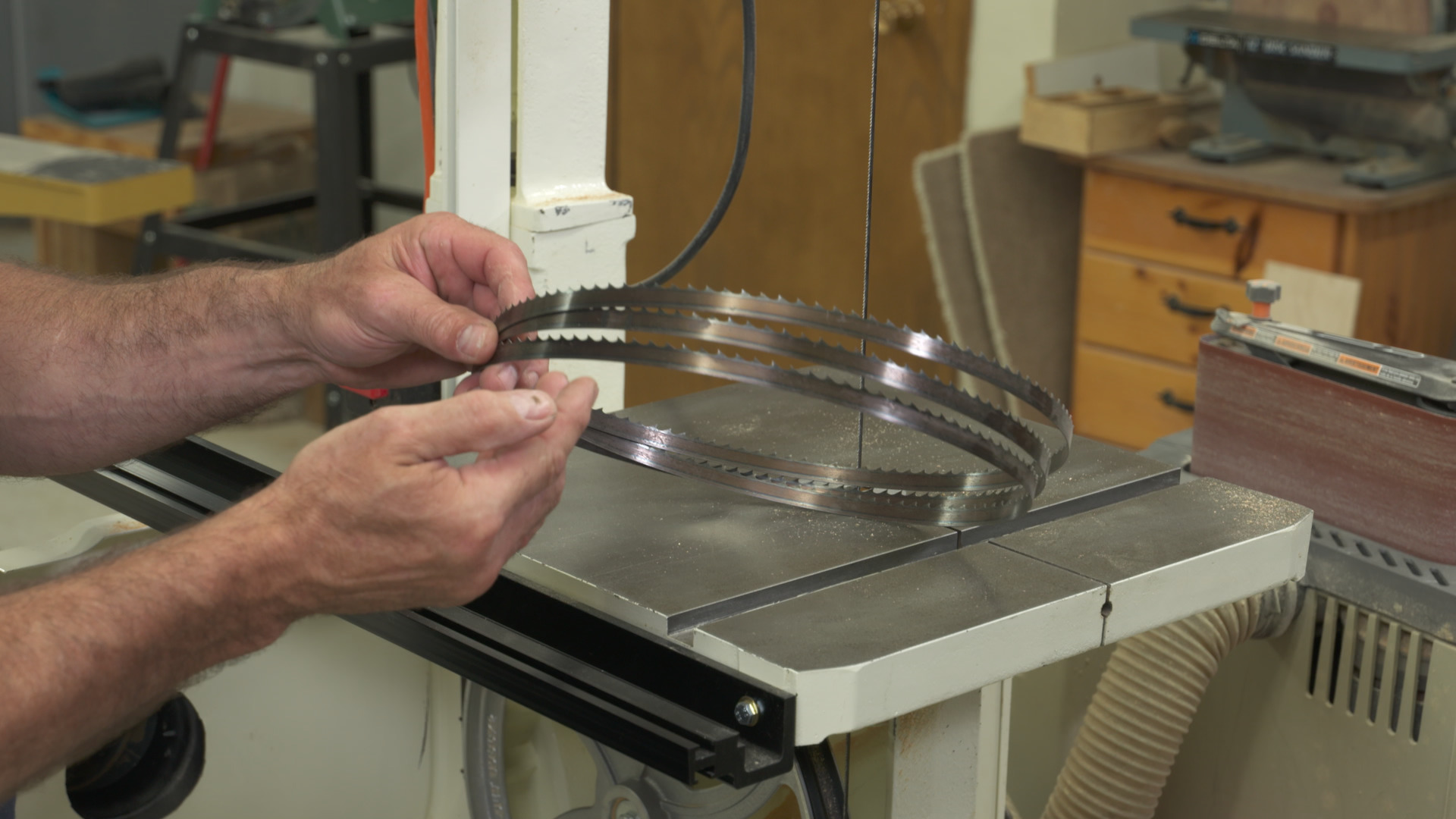

The band saw, an unsung hero in the workshop, is a powerful and versatile stationary saw that tackles a wide range of cutting tasks. Unlike its circular saw counterpart, the band saw utilizes a continuous band of toothed metal that runs along two or more wheels. This unique design allows for precise straight cuts, intricate curves, and resawing of thick lumber, making it an essential tool for woodworkers, metalworkers, and DIY enthusiasts alike.

Unveiling the Band Saw’s Cutting Prowess

Straight Cuts:

At its core, the band saw excels at delivering clean and accurate straight cuts in wood, plastic, and even metal. The continuously moving blade creates a smooth finish, minimizing chipping and tear-out, which are common issues encountered with circular saws. This makes it ideal for ripping long boards into strips or cutting plywood for cabinetry projects.

Curved Cuts:

Where the band saw truly shines is in its ability to navigate curves with exceptional control. The thin, flexible blade can effortlessly maneuver tight corners and intricate shapes. This is a game-changer for furniture makers who need to create curved components for chairs, tables, or decorative elements. With a little practice and the appropriate blade selection, achieving flawless curved cuts becomes a breeze.

Resawing:

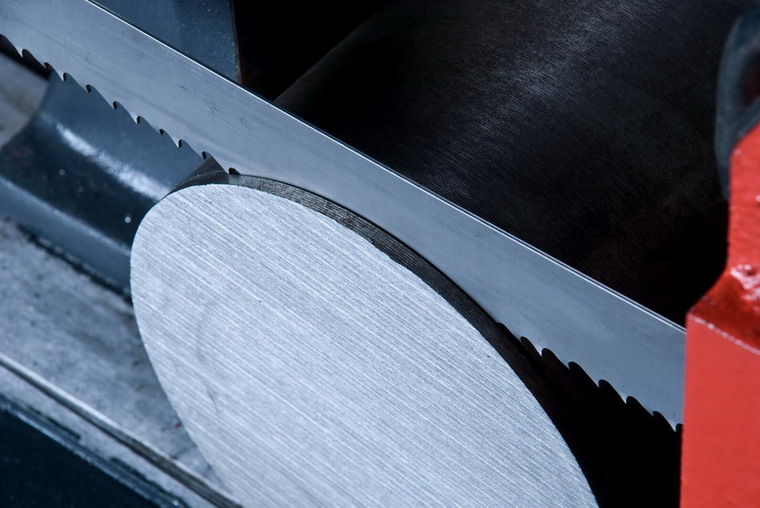

For projects requiring thin, uniform lumber, the band saw’s resawing capabilities come into play. Resawing essentially involves ripping a thicker piece of wood into multiple thinner boards. This is particularly useful for creating veneers for marquetry or crafting thin stock for intricate woodworking projects. The band saw’s adjustable blade height and precise cutting action ensure consistent thickness throughout the resawn boards.

Beyond the Basics: Specialized Band Saw Applications

While straight, curved, and resaw cuts form the foundation of band saw usage, its functionality extends far beyond these core applications. Here’s a glimpse into some specialized tasks the band saw tackles with aplomb:

-

Metalworking: With the right blade, a band saw can effectively cut through various types of metal, including steel, aluminum, and copper. This makes it a valuable tool for metalworkers who need to create custom shapes, fabricate parts, or slice pipes for plumbing projects.

-

Food Processing: Believe it or not, band saws also find application in food processing. Butchers use them to effortlessly cut through large cuts of meat into steaks, roasts, and other desired shapes. Bakeries may utilize band saws to slice cakes and pastries uniformly.

-

Flooring: When installing hardwood floors, a band saw proves adept at making intricate cuts around corners, doorways, or obstacles. This ensures a seamless and professional-looking finished floor.

Choosing the Right Band Saw for Your Needs

With such a diverse range of applications, selecting the most suitable band saw boils down to your specific needs and budget. Here are some key factors to consider:

-

Band Saw Size: Band saws come in various sizes, with the throat depth (the distance between the blade and the frame) being a crucial factor. For most woodworking tasks, a 14-inch band saw offers ample capacity. However, metalworkers or those dealing with thicker materials may benefit from a larger 18-inch or even 20-inch model.

-

Portability vs. Stationary: Band saws can be categorized as benchtop models, ideal for smaller workshops, or floor-standing models that offer more power and stability. Benchtop varieties are more compact and easier to store, while floor-standing models provide greater cutting capacity and are better suited for heavy-duty use.

-

Variable Speed Control: This feature allows you to adjust the blade speed to match the material you’re cutting. Slower speeds are ideal for delicate cuts in metal or hardwoods, while higher speeds facilitate faster cutting in softer materials.

Optimizing Your Band Saw Usage: Tips and Techniques

To maximize your band saw’s potential and ensure safe operation, here are some valuable tips:

-

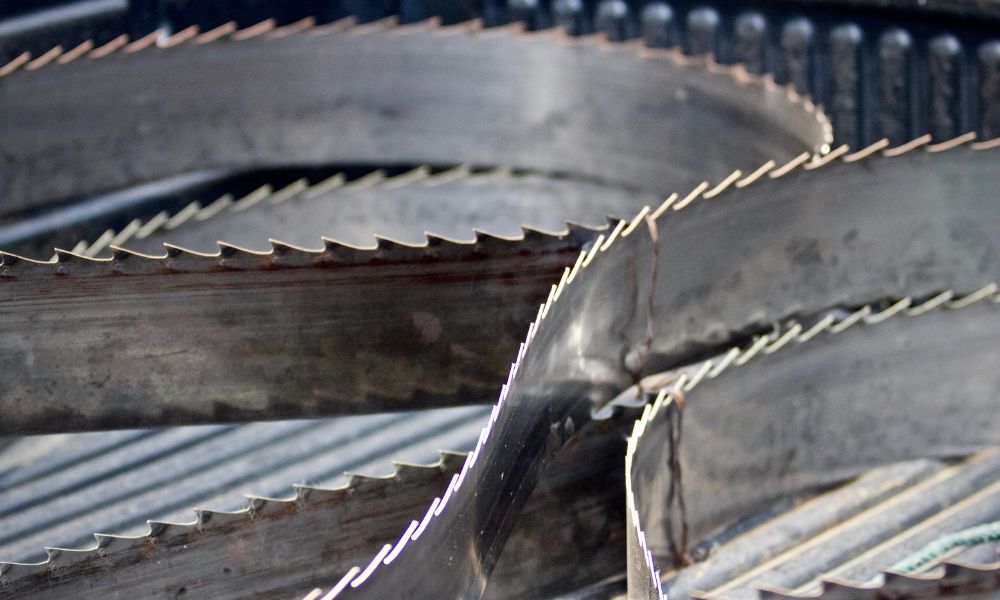

Blade Selection: The type of blade you use significantly impacts the cutting performance. Choose blades with the appropriate tooth count (TPI) for the material – higher TPI for finer cuts and lower TPI for faster, rougher cuts.

-

Blade Tension: Maintaining proper blade tension is crucial for accurate cuts and blade longevity. A dull or loose blade will wander and produce ragged cuts, while an overly tight blade can snap.

-

Feeding Material: Always feed the material into the saw at a controlled pace, applying slight but firm pressure to guide the cut. Avoid forcing the material, as this can lead to blade binding or breakage.

-

Dust Collection: Band saws generate a significant amount of sawdust. Utilize a dust collection system or shop vacuum to maintain a clean work environment and improve visibility while cutting.

Here are some additional benefits that solidify the band saw’s place in any well-equipped workshop:

-

Safety: Compared to other power saws, the band saw offers a relatively high degree of safety due to its enclosed blade and table design. However, it’s crucial to always follow proper safety protocols, such as wearing eye protection and using push sticks for narrow materials.

-

Versatility: The ability to swap out blades for different materials broadens the band saw’s application spectrum. This allows you to seamlessly transition from woodworking projects to metalworking tasks without needing dedicated equipment for each.

-

Space Efficiency: Especially when considering benchtop models, band saws offer a space-saving solution for workshops with limited square footage. Their compact design allows for efficient storage when not in use.

Incorporating a band saw into your workshop opens a door to a world of creative possibilities. With a bit of practice and the right techniques, you can unlock the full potential of this remarkable tool and elevate your woodworking, metalworking, or DIY projects to a whole new level. So, if you’re looking for a saw that offers precision, versatility, and a wide range of cutting capabilities, the band saw deserves a prominent spot on your workshop equipment wishlist.

Conclusion: The Band Saw – An Invaluable Workshop Asset

In conclusion, the band saw is a versatile and powerful tool that empowers you to tackle a wide range of cutting tasks with precision and control. From crafting intricate furniture components to resawing lumber for veneer work, the band saw’s capabilities are vast. Its ability to handle straight cuts, curved cuts, and resawing applications makes it an invaluable asset for woodworkers, metalworkers, and DIY enthusiasts alike.

Leave a Reply