The Reciprocating Saw: A Master of Demolition and More

The reciprocating saw, also known as a recip saw or Sawzall (a brand name that has become synonymous with the tool), is a powerhouse of a tool that is a must-have for any serious DIYer, demolition crew, or professional contractor. Unlike circular saws or jigsaws, which are designed for making precise cuts in wood, the reciprocating saw prioritizes brute force and versatility.

This robust saw gets its name from its reciprocating blade, which moves forward and backward at high speeds. This rapid back-and-forth motion allows the reciprocating saw to cut through a wide variety of materials, including wood, metal, plastic, and even concrete (with the right blade).

While demolition is certainly a specialty of the reciprocating saw, its uses extend far beyond tearing down walls. Here’s a closer look at the many ways you can leverage this versatile tool for your next project:

Demolition and Renovation Projects

When it comes to demolition, the reciprocating saw reigns supreme. Its ability to power through nails, screws, and even pipes makes it ideal for:

- Tearing down walls: Reciprocating saws make quick work of drywall, lath, and even some framing lumber.

- Removing windows and doors: Their cutting depth allows you to easily cut through window and door frames, making removal a breeze.

- Cutting through pipes: With the proper blade, a reciprocating saw can efficiently cut through copper, cast iron, and even PVC pipes.

- Demolishing decks and sheds: Reciprocating saws are perfect for dismantling old decks and sheds, especially when dealing with pressure-treated wood.

Rough-In Work for Plumbing, Electrical, and HVAC Systems

In the world of construction and renovation, rough-in work refers to the initial installation of electrical wiring, plumbing pipes, and HVAC ductwork. Here’s how a reciprocating saw helps:

- Cutting holes in walls and floors: Reciprocating saws are ideal for making quick cuts to create holes for running electrical wires, plumbing lines, and HVAC ducts.

- Notching joists: Notches are cutouts made in wooden beams to accommodate pipes and ductwork. Reciprocating saws make fast and easy work of this task.

Landscaping and Yardwork

The reciprocating saw isn’t just for demolition and construction tasks. It can also be a valuable tool in your yard:

- Trimming large branches: Reciprocating saws offer superior cutting power compared to loppers or pruning shears, making them ideal for tackling thick branches.

- Cutting down small trees and shrubs: While not intended for heavy-duty forestry work, reciprocating saws can handle small trees and shrubs with ease.

- Cutting through fencing: Whether you’re removing old fencing or cutting new fence posts to size, a reciprocating saw is up to the task.

Metal Cutting Applications

While not its primary function, a reciprocating saw with a dedicated metal-cutting blade can handle various metalwork tasks:

- Cutting conduit and electrical boxes: Reciprocating saws are great for cutting through metal conduit and electrical boxes.

- Disassembling metal structures: They can also be used to dismantle prefabricated metal structures such as carports or storage sheds.

- Cutting metal roofing: Reciprocating saws can be used to cut through thin metal roofing materials.

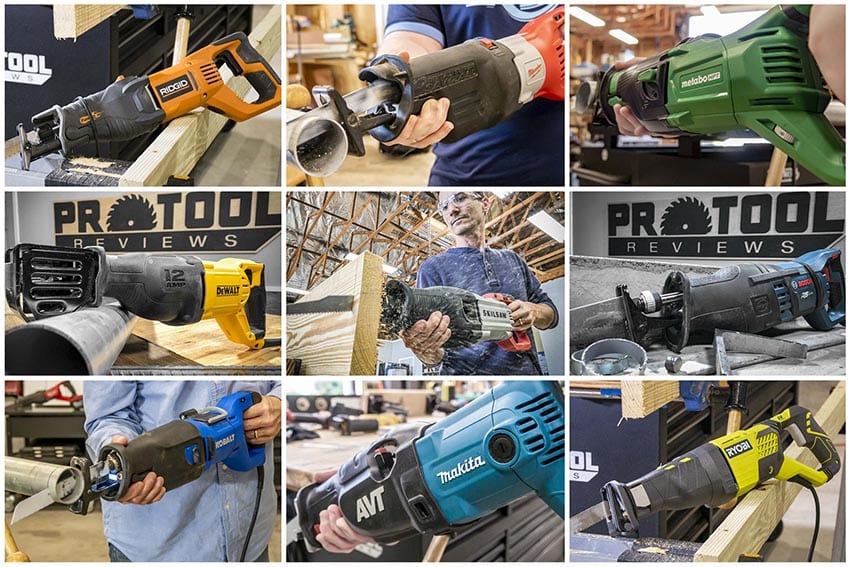

Choosing the Right Reciprocating Saw

With so many reciprocating saws available, choosing the right one depends on your needs. Here are some key factors to consider:

- Corded vs. cordless: Corded reciprocating saws offer continuous power, while cordless models provide portability and convenience.

- Amperage (corded) or battery voltage (cordless): Higher amperage or voltage translates to greater cutting power.

- Stroke length: A longer stroke length allows for deeper cuts in a single pass.

- Variable speed: A variable speed trigger allows for more precise control when cutting different materials.

- Weight and ergonomics: A lighter saw and comfortable grip will reduce fatigue during extended use.

Understanding proper handling and grip techniques

The reciprocating saw’s power makes it a valuable tool, but proper handling and grip techniques are essential for safety and efficiency. Here’s a breakdown of key techniques:

Grip:

- Two-handed grip: Always use a two-handed grip for optimal control. Your dominant hand should grip the handle closest to the blade, while your non-dominant hand grips the handle near the motor. This provides stability and reduces the risk of the saw bucking during operation.

- Thumb placement: Keep your thumbs on top of the handles, not wrapped around them. This allows you to maintain control while letting the saw do the work.

- Maintain a firm grip: The reciprocating saw can vibrate, so a firm but comfortable grip is crucial. However, avoid squeezing too tightly, as this can lead to fatigue.

Body Position:

- Stance: Stand with your feet shoulder-width apart for a stable base.

- Posture: Keep your back straight and core engaged to avoid strain.

- Leaning: When making overhead cuts, lean slightly forward to maintain your center of gravity and prevent overexertion.

Cutting Techniques:

- Straight cuts: For straight cuts, guide the saw along a straight edge or use a marking as a reference.

- Curved cuts: For curved cuts, use a slow, controlled motion and pivot at your elbows to maneuver the saw.

- Plumb cuts: When making plumb cuts (cutting vertically), brace the saw against the material for better control.

Additional Tips:

- Keep the blade straight: A misaligned blade can bind and reduce cutting efficiency.

- Let the saw do the work: Apply moderate pressure and allow the saw’s powerful motor to do the cutting.

- Cut on the pull stroke: Most reciprocating saws deliver more power on the forward stroke. However, some models offer a “orbital” setting that increases cutting efficiency on both strokes.

By following these grip, handling, and cutting techniques, you can ensure safe and efficient operation of your reciprocating saw, making it a true asset in your toolbox.

Safety First When Using a Reciprocating Saw

The reciprocating saw is a powerful tool, and safety should always be a priority. Here are some essential safety tips:

- Wear safety glasses and gloves: Eye protection is crucial to shield yourself from flying debris, and gloves will protect your hands from cuts.

- Use the correct blade: There are different blades for different materials, so ensure you’re using the appropriate blade for the job.

- Maintain a firm grip: The reciprocating saw can buck during operation, so hold it firmly with both hands.

Leave a Reply